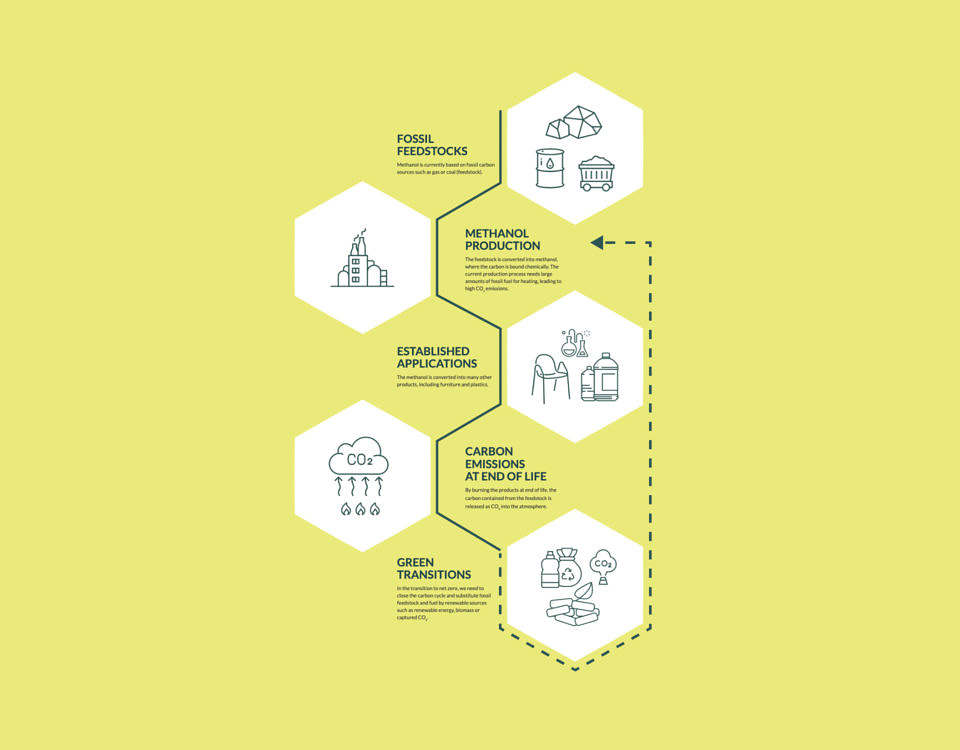

With about 110 million tons per year, methanol is one of the most-produced chemicals. It is used as a basic material for all sorts of chemical processes and products, but it comes with problems. The biggest: up until now, it has been mainly obtained from coal or natural gas. That is why it is also called black methanol, which makes up for 99,8% of all the methanol used worldwide (with 65% using natural gas and 35% coming from coal). This explains why global methanol production is responsible for 0,6% of all global GHG emissions (220 Mt CO2e in 2020). If this methanol or products made of it are combusted or otherwise oxidized, the overall carbon footprint goes up to 1% of global emissions.

Those figures alone are reason enough to find a more sustainable way to produce methanol. Yet there is another one: methanol is an emerging energy source, with great importance as a future fuel for those sectors that cannot be electrified and are hard to defossilize. Like shipping for example.

Green methanol is possible: Renewable energy can be used to electrolytically generate hydrogen from water, which is converted into methanol using CO2. The carbon for synthesizing the methanol is not supplied by fossil fuels but by CO2 from biomass or extracted from the air or industrial plants.

While the idea has been around for decades, until now it has been too expensive to produce green methanol. Thus, the share of green methanol is still at a ridiculously small 0,2%. The so-called green premium has just been too high (and the actual costs of black methanol have not been internalized).

C1 is here to change that and to bring down the green premium. The team around renowned chemist and co-founder, Dr. Marek Checinski, has developed and patented a disruptive homogeneous catalysis for the production of green methanol. The results are significant advantages in terms of investment and operating costs.

Their technology fits in small and decentralized plants, which makes it possible to go where CO2 is a waste product, and renewable energy is cheap and readily available.

Together with a changing regulatory framework, we expect a rapidly growing market for green methanol.

Building on high-performance computing and quantum chemistry C1 runs simulations to rethink chemical processes and innovation. Green methanol is the first process they disrupted, yet not the last one.

In our life cycle assessment (LCA), we evaluated the environmental impact of ramping-up green methanol production. We assessed how the environmental impacts change when green methanol displaces black methanol or conventional heavy fuel oil on the market. Our assessments show that green methanol leads to a substantial reduction in GHG emissions of up to 2.1 kg CO2-eq. per kg methanol. This is a reduction in GHG emissions of 76% when replacing heavy fuel oil in the shipping sector and 82% when replacing black methanol. Using green methanol to displace black methanol or heavy fuel oil also reduces the demand for fossil energy of up to 46 MJ per kg of methanol. This shows that C1 offers a high potential to drastically reduce GHG emissions in the chemical or shipping industry.